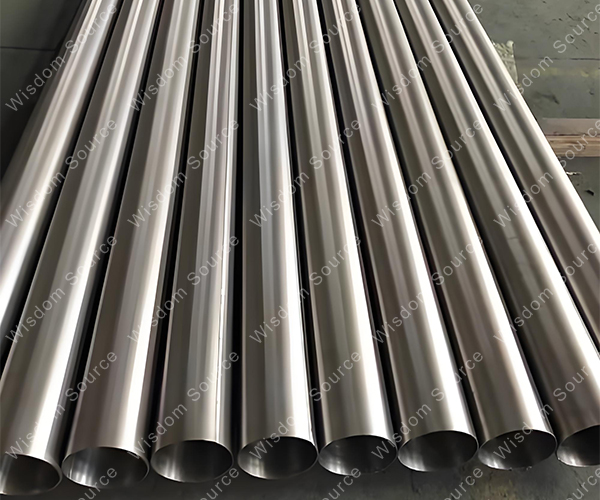

Technical Points For The Selection And Application Of Titanium Tubes In High Temperature Environments

Technical Points For The Selection And Application Of Titanium Tubes In High Temperature Environments

Under high temperature conditions, titanium

tube has become the preferred material in harsh fields such as chemical

industry and aerospace due to its excellent high temperature oxidation

resistance and corrosion resistance. Its selection and application need to be

based on rigorous technical considerations to ensure the long-term reliable

operation of the equipment.

1. Material Selection: Matching High Temperature Characteristics

Core materials: mainly industrial pure

titanium (such as Gr2) or titanium alloys (such as Ti-6Al-4V /Gr5) are

used.Pure titanium has good heat resistance and corrosion resistance below 300℃; Ti-6Al-4V alloy provides higher strength, toughness and creep

resistance at higher temperatures (about 315-400℃).

Surface treatment: If necessary, anodizing

and other processes can be used to further improve the surface hardness and

corrosion resistance in specific media.

2. Design Key: Thermal Stability And Heat Transfer Efficiency

Thermal management: In high temperature

applications, the design of titanium tubes needs to focus on thermal stability

and efficient heat exchange. Active cooling schemes such as jacket heat

exchangers or cooling water systems are often integrated to effectively control

the temperature of the pipe wall and prevent material performance degradation.

Structural design: accurately calculate and

design the thickness, diameter and other parameters of the pipe wall to ensure

that it has sufficient mechanical strength and structural stability under high

temperature and pressure.

3. Core Performance Requirements

High-temperature titanium tubes need to

meet the following key performance indicators:

Excellent high temperature stability and

oxidation resistance

Excellent corrosion resistance (especially

for acidic, chloride and other media)

Good heat conduction efficiency

High reliability (long life, low failure

rate)

Manufacturers need to carry out strict high

temperature creep testing, corrosion testing and other certifications of

materials in accordance with ASME B&PV Code, ASTM standards (such as ASTM

B338) and other specifications.

4. Typical Industrial Applications

Chemical industry: pipelines for

high-temperature corrosive media (acid, alkali, salt solution, process gas);

core components of heat exchangers and reactors.

Aerospace: Engine-related high-temperature

fluid piping system.

Energy field: part of the cooling system of

nuclear power plants; high temperature resistant seawater/steam corrosion

components in geothermal and marine energy equipment.

5. Installation And Maintenance Guarantee

Professional installation: ensure that the

pipeline support is stable, and strictly follow the manufacturer's

specifications for installation and commissioning to prevent stress

concentration.

Scientific maintenance: Establish a regular

inspection system, including cleaning the heat transfer surface (anti-fouling),

checking the status of seals, lubricating moving parts, etc., to eliminate

hidden dangers in a timely manner.

The successful application of titanium tubes in high temperature environments depends on precise material selection (pure titanium or suitable titanium alloy), optimized thermal design (integrated high-efficiency cooling system), strict quality certification (in line with ASME/ASTM and other standards), and standardized installation and maintenance. In key fields of high temperature, high pressure and strong corrosion resistance such as chemical industry and aerospace, the scientific selection and correct use of titanium tubes are an important technical basis for ensuring the safe, stable and efficient operation of equipment for a long period of time.