Analysis Of Corrosion Resistance Of Titanium Alloy In Multi-Media Environment

Analysis Of Corrosion Resistance Of Titanium Alloy In Multi-Media Environment

For its unique physical and chemical properties, titanium and titanium alloys show excellent corrosion resistance in chemical industry, environmental protection, marine engineering and other fields, but their corrosion resistance is significantly affected by the composition of the medium, temperature and alloying elements. This paper systematically combs the corrosion behavior and mechanism of titanium alloys in different media environments, and provides a theoretical basis for engineering applications.

1. Corrosion Resistance In Chlorine-Containing Media

1) Stable performance in wet chlorine system

Titanium exhibits excellent corrosion resistance in wet chlorine gas and non-high temperature and high concentration chloride solutions (except ZnCl₂, AlCl, CaCl₂).The dense oxide film (TiO₂) formed on its surface can effectively block the penetration of chloride ions and has been widely used in bleaching plants, electrolytic chlorine plants and wastewater treatment plants. However, in high-concentration chloride solutions at high temperatures (>100℃), titanium is prone to crevice corrosion, especially when in contact with organic materials such as polytetrafluoroethylene, the local hypoxic environment accelerates the destruction of the oxide film, resulting in a significant increase in the corrosion rate.

2) Dangerous reactions in dry chlorine systems

Dry chlorine gas has a violent exothermic reaction with titanium (Ti + 2Cl → → TiCl → + ΔH), and the heat released can cause spontaneous combustion or even explosion. The reaction product titanium tetrachloride (TiCl4) continues to evaporate under low humidity conditions, exacerbating the combustion process.Studies have shown that industrial pure titanium needs to maintain more than 1.5% moisture in chlorine gas at 200℃ to maintain a blunt state; the water content at room temperature needs to be ≥0.3%~0.4%. Titanium-palladium alloy and titanium-nickel-molybdenum alloy can reduce the critical moisture content to less than 0.1% by optimizing the alloy composition, significantly improving safety.

3) Adaptability of chlorine-containing compound solutions

Titanium has good corrosion resistance to solutions of chlorine-containing compounds such as chlorate, chlorite, hypochlorite and perchlorate, but high temperature and high concentration conditions need to be avoided. For example, in the production of electrolytic sodium hypochlorite, titanium-based anodes have become an ideal material to replace graphite due to their corrosion resistance and electrical conductivity.

2. Differentiated Performance In Halogen Media

1) Stability of bromine and iodine systems

The corrosion resistance mechanism of titanium in bromine and iodine environments is similar to that of chlorine. It is necessary to promote the regeneration of the surface oxide film by maintaining trace amounts of moisture in the medium (usually ≥0.5%). In the seawater desalination plant, the titanium tube heat exchanger was exposed to the bromine-containing ion environment for a long time, and there were no obvious signs of corrosion.

2) The achilles heel of the Fluorine system

The corrosion resistance of titanium in fluorine, hydrofluoric acid and acidic fluoride solutions decreases sharply, and even very low concentrations (such as 0.1% HF) can destroy the oxide film. Its corrosion rate can reach more than 10 times that of the chlorine system, and it lacks an effective corrosion inhibitor. The exception is that fluorides (such as NAAlALF1) or fluorocarbon compounds (such as PTFE) that form stable complexes with metal ions have basically no corrosive effect on titanium because the activity of fluorine ions is suppressed.

3. The Synergistic Effect Of Alloying Modification

By adding elements such as palladium, nickel, molybdenum, etc., the corrosion resistance threshold of titanium alloy can be significantly improved:

Titanium-Palladium Alloy: The element palladium promotes the repair of oxygen vacancies in the oxide film, reducing the critical moisture content to 0.05%.

Titanium-Nickel-Molybdenum Alloy: Nickel and molybdenum form a solid solution, which enhances the stability of the oxide film in the reducing medium, and is suitable for mixed acid environments containing Cl⁻and SOO2⁻.

Titanium Zirconium Alloy: The addition of zirconium refined the grain structure and improved the resistance to crevice corrosion, which is outstanding in marine engineering.

4. Engineering Application Recommendations

1) Medium Composition Control: In the chlorine-containing process, the moisture content and temperature need to be strictly monitored to avoid entering the high-temperature and high-concentration corrosion zone.

2) Material Selection Principle:

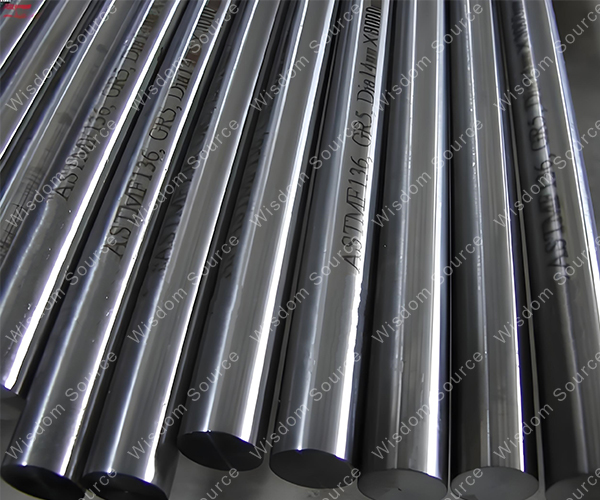

Industrial pure titanium (Gr1 / Gr2) is preferred in wet chlorine environments;

Nitrogen isolation is required for dry chlorine operation or titanium-palladium alloy is used instead;

Fluorine-containing systems should avoid the use of titanium and choose hastelloy or Monel alloy instead.

3) Structural Design Optimization: avoid direct contact between titanium and organic materials, and use coating or electro-chemical protection to reduce the risk of crevice corrosion.

The corrosion resistance of titanium alloy has a distinctive medium dependence, and its characteristics of “forming and oxidizing film, losing and oxidizing film” require precise engineering control. Through alloying modification and process optimization, the application boundaries of titanium alloys in harsh and corrosive environments are constantly expanding, providing key material support for the longevity of chemical equipment. Future research needs to further reveal the dynamic repair mechanism of the oxide film and develop a fourth-generation titanium alloy suitable for supercritical chlorine systems.