Laser Cutting Titanium Material: Process, Influencing Factors And Analysis Of Finished Product Effect

Laser Cutting Titanium Material: Process, Influencing Factors And Analysis Of Finished Product Effect

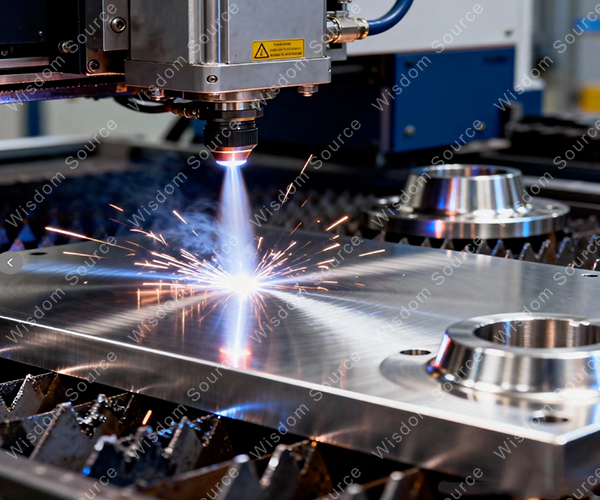

As an advanced processing technology, laser cutting has been widely used in many industrial fields due to its advantages of high precision and high efficiency. It uses a focused high-power density laser beam to scan the surface of the workpiece, and locally heats the material to thousands or even tens of thousands of degrees Celsius in a very short period of time, so that the irradiated material quickly melts, vaporizes, cauterizes or reaches the ignition point. At the same time, the molten material is blown away by means of a high-speed air flow coaxial with the beam, so as to achieve the purpose of cutting the workpiece. In the field of titanium material processing, laser cutting also shows unique value, but its effect is affected by a variety of factors, and the finished product will show specific characteristics.

1. The Main Factors Affecting The Effect Of Laser Cutting

1) Process Parameters Of Laser Cutting

There are many key parameters to measure the quality of laser cutting technology and machining, among which laser power is an extremely important one. The size of the laser power directly determines the energy carried by the laser beam, which in turn affects the heating effect of the material. Insufficient power may not make the material reach the temperature required for melting, gasification, etc., resulting in the cutting cannot be carried out smoothly; if the power is too high, it may cause excessive ablation of the material, affecting the cutting accuracy and surface quality. Therefore, reasonable selection of laser power is the basis for ensuring the quality of laser cutting.

2) Cutting Speed

Cutting speed is another important influencing factor in the laser cutting process. Under normal circumstances, there is a close connection between laser energy, material thickness, and cutting gas pressure and cutting speed. The higher the laser energy, the more heat is transmitted to the material per unit time, and the faster the material can reach the state required for cutting. Therefore, under the same other conditions, the cutting speed can be increased accordingly; The smaller the material thickness, the easier it is for the laser to penetrate the material, and the cutting speed can be accelerated; the greater the pressure of the cutting gas, the stronger the ability to blow off the molten material, which also helps to improve the cutting speed. Conversely, if the laser energy is low, the material thickness is large, and the cutting gas pressure is small, the cutting speed will slow down.

However, in actual on-site operations, high cutting speeds cannot be pursued blindly. Especially for some mechanical parts with complex shapes, a balance needs to be found between cutting speed and cutting quality. Too fast cutting speed may lead to quality problems such as irregular cutting edges and burrs, which affect the overall performance of the product; while too slow cutting speed will reduce production efficiency and increase production costs. Therefore, the operator needs to reasonably adjust the cutting speed according to the specific part shape, material characteristics and other factors to ensure product quality.

3) Gas Pressure

The gas sprayed during the laser cutting process plays a vital role. On the one hand, the gas can melt and cut metal materials, and rely on its pressure to blow the liquid metal away, thereby forming a neat incision. If the gas pressure is insufficient and the molten material cannot be effectively blown away, it will cause residual slag at the incision and affect the cutting quality; on the other hand, the gas has a cooling effect on the raw material, which can take away part of the energy from the cutting area, reduce the heat-affected area of the material, and reduce thermal deformation. Therefore, the size of the gas pressure has an important impact on the cutting quality.

In the processing of titanium materials, an inert gas (such as argon or nitrogen) needs to be used as an auxiliary gas. This is because titanium materials can easily react with oxygen at high temperatures, resulting in oxidation, which affects the performance and quality of the material. The use of inert gas can effectively reduce the problem of oxidation contaminating the material, and ensure the cutting quality and material performance.

2. Effect Of Laser Cutting Of Titanium Material On Finished Products

1) Burr Problem

In the laser cutting process of titanium materials, argon or nitrogen gas is generally used as an auxiliary gas. Although a little sticky residue may be produced at the bottom of the slit, these sticky residues are easy to remove. However, since the incision will absorb a certain amount of oxygen during the cutting process, a hard and brittle oxide layer will be produced on the surface of the incision, forming burrs. This oxide layer will not only affect the appearance quality of the parts, but may also have a certain impact on the assembly and performance of the parts. Therefore, after the cutting is completed, subsequent processing of the incision, such as sanding, polishing, etc., is usually required to remove the oxide layer and burrs and improve the quality of the parts.

2) Deformation Problem

Titanium materials generate a lot of heat during laser cutting. With the extension of processing time, the product will gradually accumulate heat, resulting in thermal deformation. Moreover, due to the different processing times of the first product and the last product, there are also differences in the accumulated heat, so the amount of deformation will be different. If the heat cannot be reduced in a timely and effective manner, the amount of deformation of the product will be further increased, seriously affecting the dimensional accuracy and shape accuracy of the product. In order to reduce deformation, some measures can be taken, such as optimizing the cutting sequence, controlling the cutting parameters, and adopting cooling devices to reduce the heat accumulation during the cutting process and ensure the quality of the product.

Laser cutting titanium materials has unique advantages, but it also faces some challenges. Understanding the main factors that affect the effect of laser cutting and the impact of laser cutting of titanium materials on finished products is of great significance for optimizing the cutting process and improving product quality. In actual production, the operator needs to reasonably adjust the process parameters according to the specific circumstances, select the appropriate auxiliary gas, and take effective anti-deformation measures to achieve efficient and high-quality laser cutting of titanium materials.